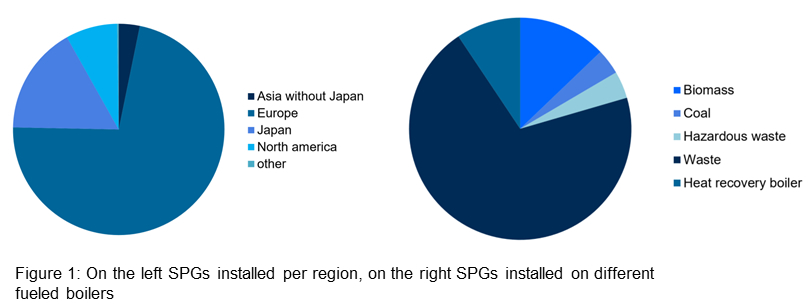

The Shock Pulse Generator (SPG), developed and manufactured by the Swiss company Explosion Power GmbH, is an online boiler cleaning equipment. The innovative technology has proven its outstanding performance at more than 400 installations in 20+ countries since 2009 (cf. Figure 1). Plant operators confirmed significant prolongation of boiler operating periods and increased efficiency, thus contributing to a sustainable and economic plant operation. Following the initial launch onto the European market for residential waste as fuel, this innovative technology has become available virtually everywhere in the world in the meantime, thanks to the corresponding partnerships.

Application example of the coal-fired power plant at Werdohl Elverlingsen (DE), Block E4, Reheater 1

The Elverlingsen coal-fired power plant is operated by Mark- E, a company of the ENERVIE Group, and Block E4 has an electrical output of 321 MW. This is a Benson steam generator with 2 chambers, and double U-firing. The dimensions of the steam generator are approx. 11 x 13 x 80 meters. Reheater 1 has been cleaned by two SPGs since September 2011, and three soot blowers have thereby been shut down. In addition to the steam saving, the service life of Reheater 1 has been considerably extended, as the damage caused by abrasion and/or erosion has been reduced.

Application example of the Zurich Josefstrasse WtE plant (CH), radiation passes

The four-pass horizontal boiler has got a radiation pass width of 7.2 m and processes up to 13.25 t/h of waste, including up to 15% sewage sludge. The steam capacity is 52 t/h at 40 bar and 400 °C. The third radiation pass is separated by a membrane evaporation wall, subdividing the pass into a left and a right half. A maximum flue gas temperature of 700 °C should not be exceeded at the inlet of the horizontal pass, in order to prevent excessive corrosion rate of superheater tubes.

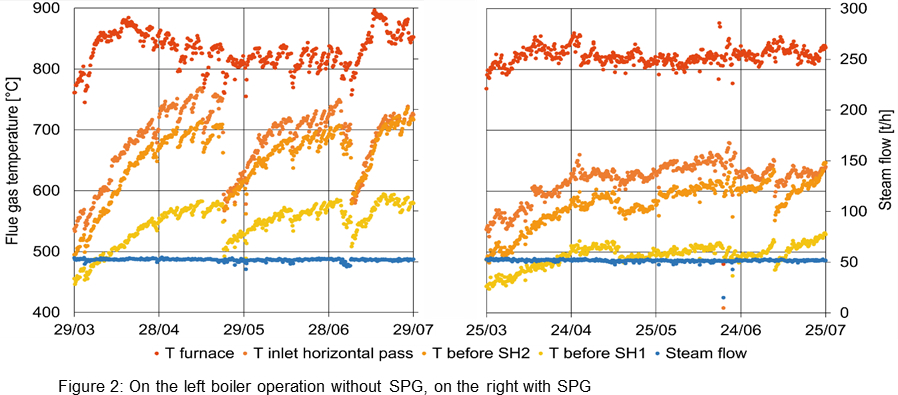

In 2016, one Shock Pulse Generator TwinL was installed at the lower part of the 2nd radiation pass, to improve the cleaning of the radiation passes. In 2015 (cf. Figure 2 on the left), without Shock Pulse Generator, the flue gas temperature at the inlet of the horizontal pass increased almost linearly, 7°C per day, and reached the critical value of 700°C less than one month after boiler start up. By using the shower cleaning system, the temperature could be kept around 700°C for 2-3 weeks. In order to avoid a further increase of the temperature, a manual online boiler cleaning was carried out, which reduced the temperature to a similar value as after the maintenance stop. Thereafter, the periods until shower cleaning and manual boiler cleaning were again necessary, became shorter and shorter.

After the installation of the Shock Pulse Generator (cf. Figure 2 on the right), the flue gas temperature at the inlet of the horizontal pass increased in the first month to 600 °C but could then be kept within 600 to 650 °C for the rest of the 4 months operating period. The Shock Pulse Generator was commissioned one week after boiler start up. During week two and three the interval between Shock Pulses was 4 hours, during week four to five two hours and from week six onward 1 hour.

Further to the positive result of the reduced flue gas temperature and therefore lower corrosion rate at superheater bundles, the operator noticed positive effects for the additional manual online cleaning at the horizontal pass, which could be reduced from 3 to 1 intervention per 6 months operation. Additionally, the sand blasting during the maintenance stop could be carried out faster and less material needed to be disposed. Last but not least, the reduction of the flue gas temperature will allow overload operation of the boiler during periods with peak demand of the district heating.

The Shock Pulse Generator enables us to run our district heat production on maximum performance all year long. Dr. Dettwiler, Operating manager Zurich Josefstrasse WtE plant